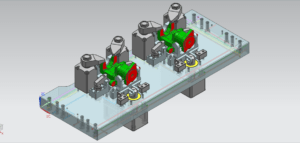

Special fixtures 专用夹具

$40.00

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nulla congue vitae sem nec fermentum. Maecenas tincidunt semper cursus. In sit amet posuere augue. Curabitur tempus nec justo et consequat. Aliquam non ex lectus. Etiam vel ultricies felis. In sed mauris felis. Duis egestas nec quam at vulputate. Nulla nec odio rhoncus, gravida mi congue, bibendum urna. Fusce vel iaculis tortor. Praesent lacus justo, blandit non molestie sit amet, iaculis vitae nunc. Ut sapien diam, lobortis non metus non, fringilla molestie ante. Mauris nisl quam, ultricies a fringilla ac, rutrum nec dolor. Cras luctus viverra odio.

Description

According to the type of machine tool used, it can be divided into lathe fixtures, milling machine fixtures, drilling machine fixtures, boring machine fixtures, machining center fixtures and other machine tool fixtures.

According to the power source that drives the fixture, it can be divided into manual fixtures, pneumatic fixtures, hydraulic fixtures, electric fixtures, magnetic fixtures, vacuum fixtures and self-clamping fixtures.

Here are a few fixtures classified by degree of specialization:

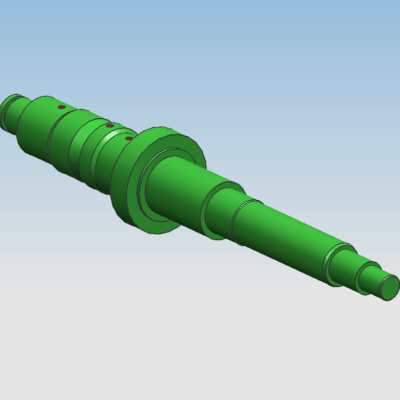

NO. 1, universal fixture

Universal fixture refers to a standardized fixture. It is an accessory of a general machine tool and can be used to process different workpieces. It has great versatility, such as three-jaw self-centering chucks and four-jaw chucks, flat vises, dividing heads and rotary tables. They are often used by users in a matching way with machine tools to ensure the performance of the machine tools. Universal fixtures are mainly used in single-piece and small-batch production. Generally, they do not need to be adjusted or slightly adjusted when used. This type of fixture is produced by a special factory and can be purchased on the market. It does not need to be designed and manufactured by the user unit.

NO. 2. Special fixtures

Special fixtures refer to fixtures designed and manufactured for a certain process of a certain workpiece. Special fixtures do not need to consider universality, as long as they have a reasonable structure, convenient operation, high production efficiency, and easy to ensure the processing accuracy of the workpiece. Special fixtures require special design and manufacturing, with a long production cycle and high cost. They cannot be used when the product is updated or modified. Therefore, it is suitable for mass production of fixed products.

NO. 3. Combination fixtures

Combination fixtures are special fixtures assembled according to requirements from a set of pre-manufactured standard components and parts. It has the characteristics of a special fixture. When the product changes, it can be easily disassembled into standard components to be combined into a new fixture. Therefore, combination fixtures are suitable for CNC machining, trial production of new products, and single-piece small-batch production. The combination fixture also has the advantages of short production preparation cycle, reusable components, low cost, and can reduce the variety, quantity and storage area of special fixtures. It is also widely used in some batch production.

NO. 4. Adjustable fixture

Adjustable fixtures include general adjustable fixtures and special adjustable fixtures. Both can process a certain range of workpieces by adjusting or replacing a small number of components. They have the advantages of general fixtures and special fixtures. The general adjustable fixture has a wide range of applications, and the processing object is not very clear; the special adjustable fixture is designed according to the group process requirements for a group of workpieces with similar shapes and sizes and similar processing technology. Its processing object and range are very clear, and it is also called a group fixture.

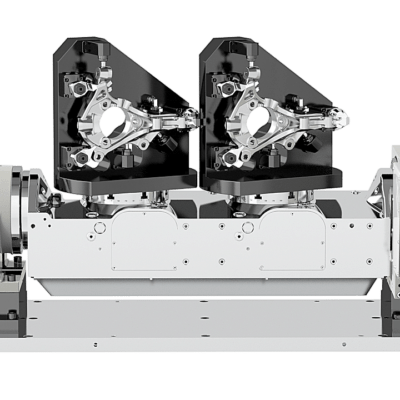

NO. 5. Hydraulic combination vise

Hydraulic combination vise is a general combination fixture that can realize mass production. The unique structural design can meet the processing needs of single or multiple clamps, clamp simultaneously within 4 seconds, and can be freely selected according to the machine model and workbench size. It can maximize the capacity of the machine workbench, thereby increasing production capacity, and can save 30%~200% of the processing and clamping time in the mass production cycle, thereby improving production efficiency. For enterprises engaged in mass production, this universal combination clamp is the first choice!

Each clamp has its own advantages, and we must choose the appropriate clamp to cooperate with the processing according to our own processing needs. For mass production processing, I personally think that the hydraulic combination vise is currently the best choice, and this clamp is very suitable for mass production.

Reviews

There are no reviews yet.