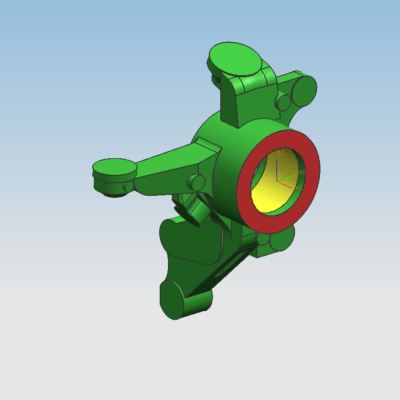

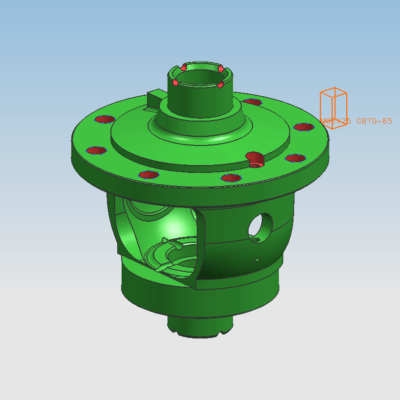

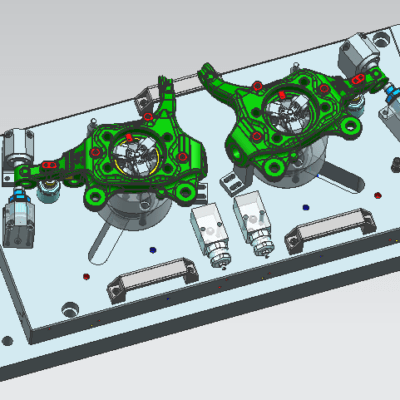

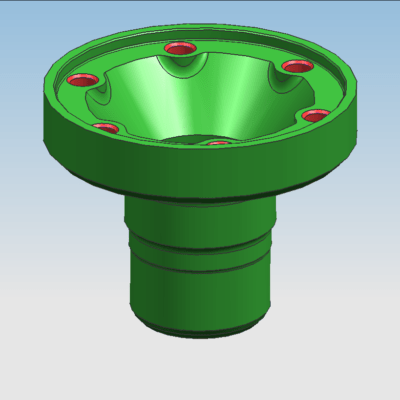

Steering knuckle

$48.00

Description

Hangzhou Xiongchu Technology Co., Ltd. was established in 2013. At the beginning of its establishment, it was based on the design of non-standard automated fixtures, and also covered the provision of complete line delivery solutions such as tools, inspection fixtures, and machine tool processing centers. It specializes in providing “turnkey” services to customers. The company’s R&D technicians account for more than 70%, and have rich project experience in the precision machinery parts processing industry, the lightweight field of automobile chassis, and the manufacturing and processing of aircraft and aviation parts. After nearly 10 years of growth, Hangzhou Xiongchu has now become a “smart factory” solution integrator. Whether it is new factory planning or the renewal and upgrading of old production lines, one-stop service can be provided.

| Item | Unit | LW400V | LW500V | LW650V |

| Processing range | ||||

| X/Y/Z axis travel | mm | 800/360/400 | 820/520/500 | 820/520/500 |

| B axis rotation angle | Deg. | ±120 | ±120 | ±120 |

| C axis rotation angle | 360 | 360 | 360 | |

| Distance from spindle nose to worktable | mm | 150-550 | 150-650 | 150-650 |

| Max. processing Dia. & height of workpiece | mm | Φ360×400 | Φ520×480 | Φ520×480 |

| Work table | ||||

| Table size | mm | Φ400 | Φ500 | Φ650 |

| Table load | Kg | 200 | 300 | 300 |

| T-slot (number x width x spacing) | mm | 8×14×45 | 5×14×100 | 5×14×100 |

| Feed system | ||||

| X/Y/Z axis rapid feed | m/min | 36/36/36 | 36/36/36 | 36/36/36 |

| Max. speed of B/C axis | rpm | 100/150 | 60/100 | 60/100 |

| X/Y/Z axis motor torque | Nm | 20/20/20 | 27/27/27 | 27/27/27 |

| B axis rated/Max. torque | Nm | 335/640 | 2000/3600 | 2000/3600 |

| C-axis rated/Max. torque | Nm | 106/203 | 600/1100 | 600/1100 |

| Spindle system | ||||

| Spindle drive mode | direct type | direct type | direct type | |

| Spindle Max. speed | rpm | 12000 | 12000 | 12000 |

| Spindle rated power | kW | 11 | 11 | 11 |

| Spindle Max. torque | Nm | 120 | 120 | 120 |

| Tool shank specifications | BT40 | BT40 | BT40 | |

| Tool changing system | ||||

| Tool magazine capacity | pcs | 24 | 24 | 24 |

| Tool change time (T-T) | Sec. | 2 | 2 | 2 |

| Accuracy | ||||

| X/Y/Z repeat positioning accuracy | mm | ≤0.006/0.004/0.004 | ≤0.006/0.004/0.004 | ≤0.006/0.004/0.004 |

| X/Y/Z positioning accuracy | mm | ≤0.008/0.006/0.006 | ≤0.008/0.006/0.006 | ≤0.008/0.006/0.006 |

| B/C axis repeat positioning accuracy | Sec. | ≤6 | ≤6 | ≤6 |

| B/C axis positioning accuracy | Sec. | ≤12 | ≤12 | ≤12 |

| Others | ||||

| CNC system | Siemens one | Siemens one | Siemens one | |

| Machine weight | kg | 8500 | 11000 | 11000 |

|

Business Type

|

Factory / Manufacturer

|

Tolerance

|

+/-0.01mm ~ +/-0.05mm

|

|

|

Service

|

CNC Machining,Turning and Milling,CNC Turning,OEM /ODM Parts

|

|||

|

Material

|

1). Aluminum: AL 6061-T6, 6063, 7075-T etc 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc

3). Steel: 4140, Q235, Q345B,20#,45# etc.

4). Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc

5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc

6). Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc.

|

|||

|

Finish

|

Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish. Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing.

electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench).

Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc.

|

|||

|

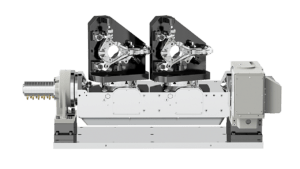

Main Equipment

|

CNC Machining center(Milling), CNC Lathe, Grinding machine,

|

|||

|

Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc.

|

||||

|

Drawing format

|

STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples.

|

Surface roughness

|

Ra 0.1~3.2

|

|

|

Inspection

|

Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM

|

|||

|

Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge

|

||||

|

Capacity

|

CNC turning work range: φ0.5mm-φ150mm*300mm

|

|||

|

CNC milling work range: 510mm*1020mm*500mm

|

||||

Reviews

There are no reviews yet.