Showing 17–32 of 32 results

-

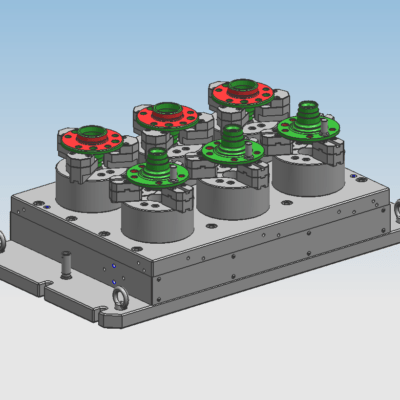

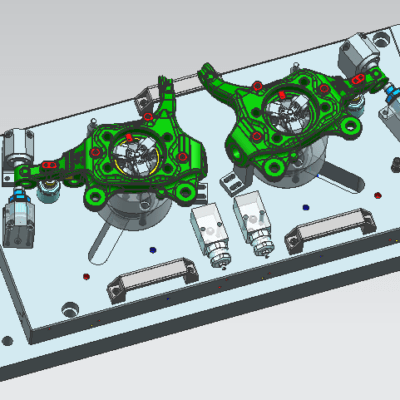

夹具描述:夹具采用零件中心定位、菱形销角向定位、端面轴向定位,上端面夹紧加工侧面各孔及凸台面。 Fixture description: The fixture adopts the central positioning of the parts, the angular positioning of the diamond pin, the axial positioning of the end face, and the upper end face clamping the side holes and the convex table.

-

夹具描述:夹具采用零件中心定位、菱形销角向定位、端面轴向定位,端面夹紧加工侧面各孔及凸台面。 Fixture description: The fixture adopts central positioning of parts, angular positioning of diamond pin, axial positioning of end face, end face clamping processing of the side holes and convex mesa.

-

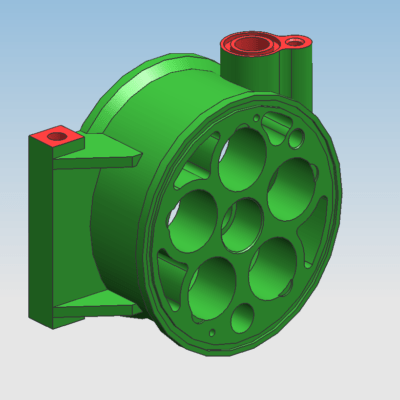

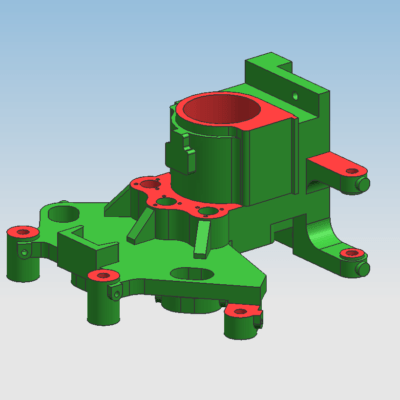

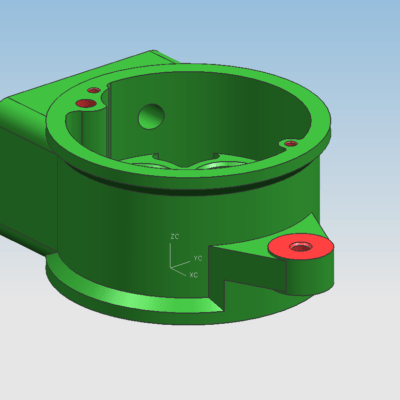

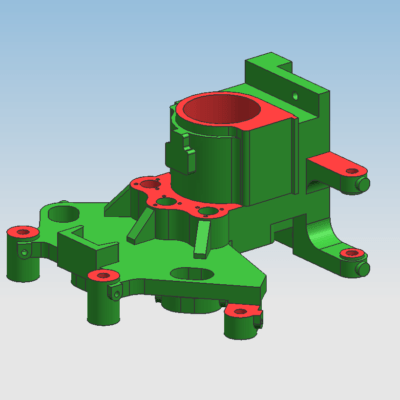

夹具描述:夹具采用零件中心孔定位、侧面凸轴限角向、上下端面夹紧加工正面凸台及各孔。 Fixture description: The fixture adopts the center hole positioning of the parts, the side convex shaft is limited to the Angle, and the upper and lower end face clamping processing the front convex table and the holes.

-

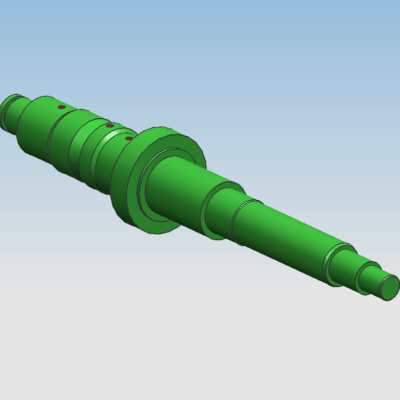

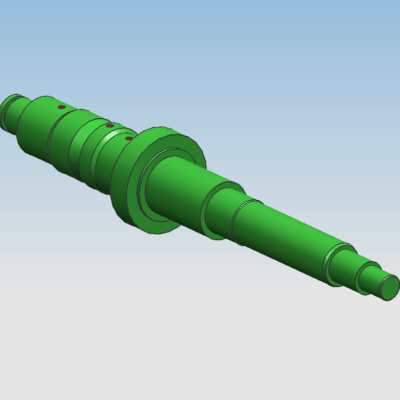

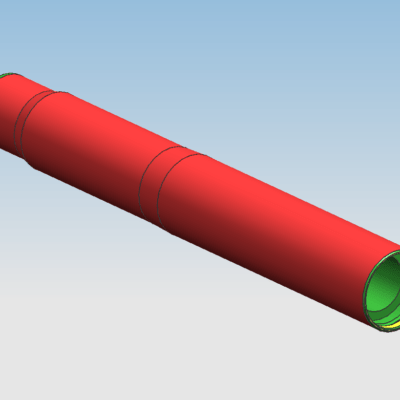

夹具描述:夹具采用V型块支撑定位、两端夹紧方式加工轴面上各孔。 Fixture description: The fixture adopts V-shaped block support positioning and clamping at both ends to process the holes on the shaft surface.

-

-

夹具描述:夹具采用车床拉杆手动夹紧定位、挡板限角向方式车加工端面。 Fixture description: The fixture uses a lathe pull rod to manually clamp and position, and a baffle to limit the angle of the end face.

-

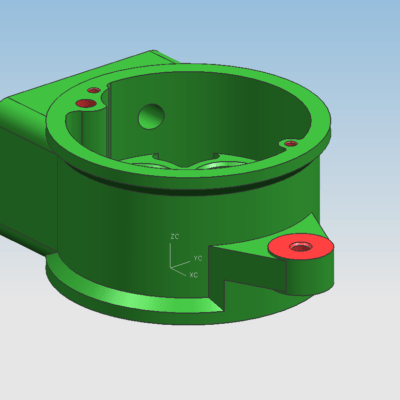

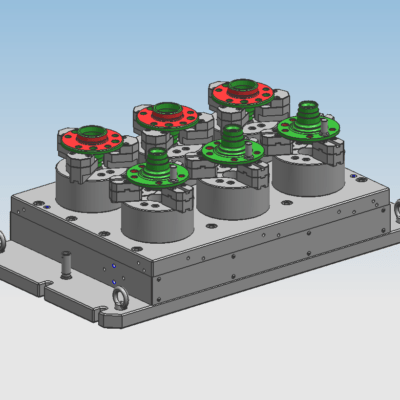

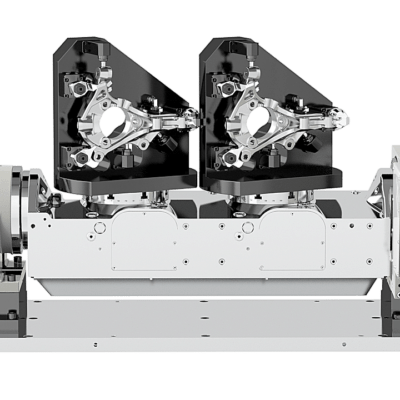

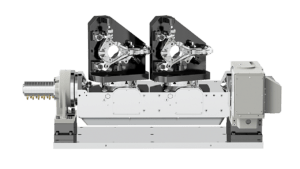

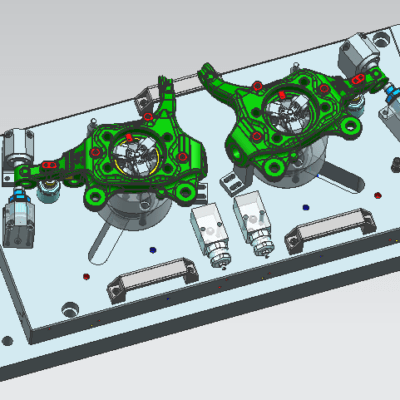

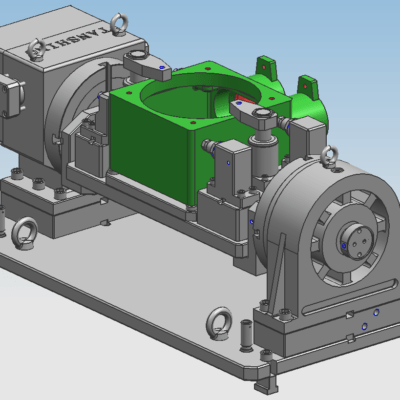

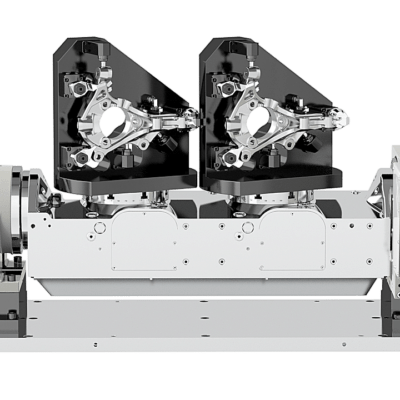

夹具描述:夹具采用第四轴旋转、端面定位、中心拉缸夹紧方式钻攻外圆螺纹孔及铣槽;端面定位、中心拉缸加紧钻攻端面螺纹孔。 Fixture description: The fixture uses the fourth axis rotation, end face positioning, the center cylinder clamping mode to drill and tap the external round thread hole and milling groove; Face positioning, center cylinder tightening drilling face thread hole.

-

夹具描述:夹具采用零件侧面和中段两侧面定位、手动夹紧加工正上面台阶面。 Fixture description: The fixture uses the side and middle sides of the part for positioning and manual clamping to process the top step surface.

-

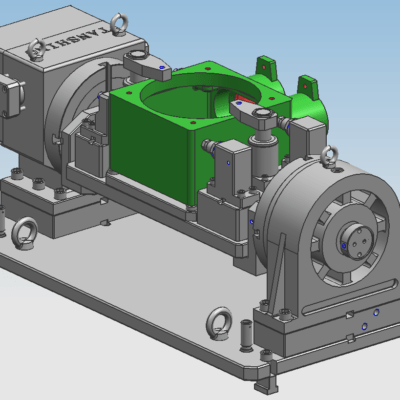

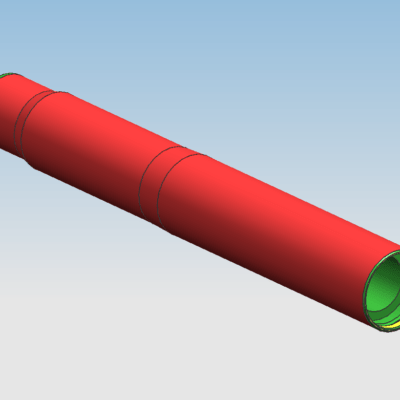

Product name: Mandrel Clamp description: The clamp uses a three-claw clamp to locate the outer circle and end surface, and the second sequence uses a pin to determine the angle and process the red part of the part.

-

-

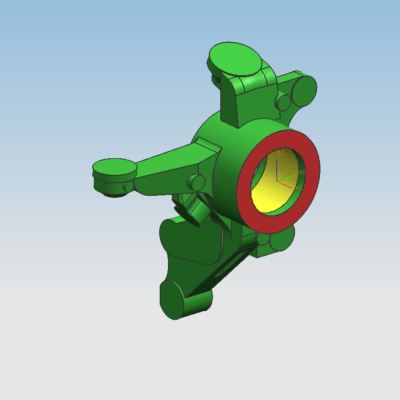

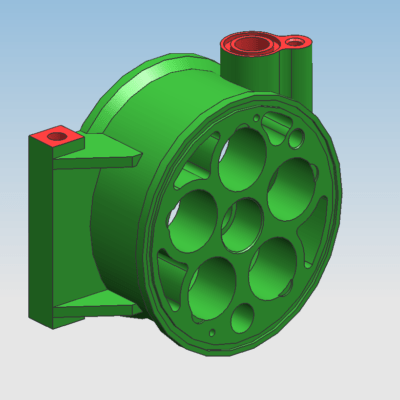

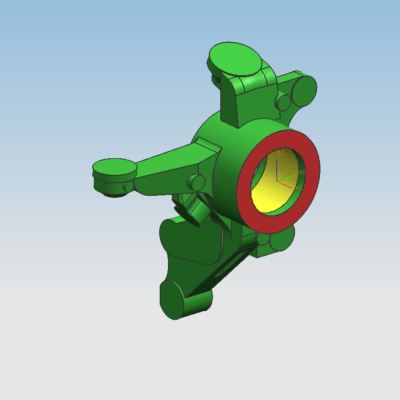

夹具描述:夹具采用叉脚定角向,轴面夹紧方式钻镗内孔及其一叉脚;后序采用前序两孔定位、叉角定角向、轴面夹紧加工另一叉角孔。 Fixture description: The fixture adopts the Angle Angle of the foot, the axial surface clamping way to drill and boring the inner hole and its one foot; The other fork Angle hole is processed by presequence two-hole positioning, fork Angle orientation and axial surface clamping.

-

$40.00

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nulla congue vitae sem nec fermentum. Maecenas tincidunt semper cursus. In sit amet posuere augue. Curabitur tempus nec justo et consequat. Aliquam non ex lectus. Etiam vel ultricies felis. In sed mauris felis. Duis egestas nec quam at vulputate. Nulla nec odio rhoncus, gravida mi congue, bibendum urna. Fusce vel iaculis tortor. Praesent lacus justo, blandit non molestie sit amet, iaculis vitae nunc. Ut sapien diam, lobortis non metus non, fringilla molestie ante. Mauris nisl quam, ultricies a fringilla ac, rutrum nec dolor. Cras luctus viverra odio.

-

夹具描述:夹具采用零件两垂直面定位、螺杆支撑、四轴旋转、手动夹紧加工各凸台面及各孔。 Fixture description: The fixture uses two vertical surfaces of the part to position, screw support, four-axis rotation, and manual clamping to process each boss surface and each hole.

-

-

-

$35.00

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nulla congue vitae sem nec fermentum. Maecenas tincidunt semper cursus. In sit amet posuere augue. Curabitur tempus nec justo et consequat. Aliquam non ex lectus. Etiam vel ultricies felis. In sed mauris felis. Duis egestas nec quam at vulputate. Nulla nec odio rhoncus, gravida mi congue, bibendum urna. Fusce vel iaculis tortor. Praesent lacus justo, blandit non molestie sit amet, iaculis vitae nunc. Ut sapien diam, lobortis non metus non, fringilla molestie ante. Mauris nisl quam, ultricies a fringilla ac, rutrum nec dolor. Cras luctus viverra odio.