Classification of fixtures

A fixture is a device used to fix the object to be processed in the mechanical manufacturing process so that it occupies the correct position for construction or inspection. It is also called a fixture (qiǎ jǜ). In a broad sense, any device used to quickly, conveniently and safely install the workpiece in any process of the process can be called a fixture.

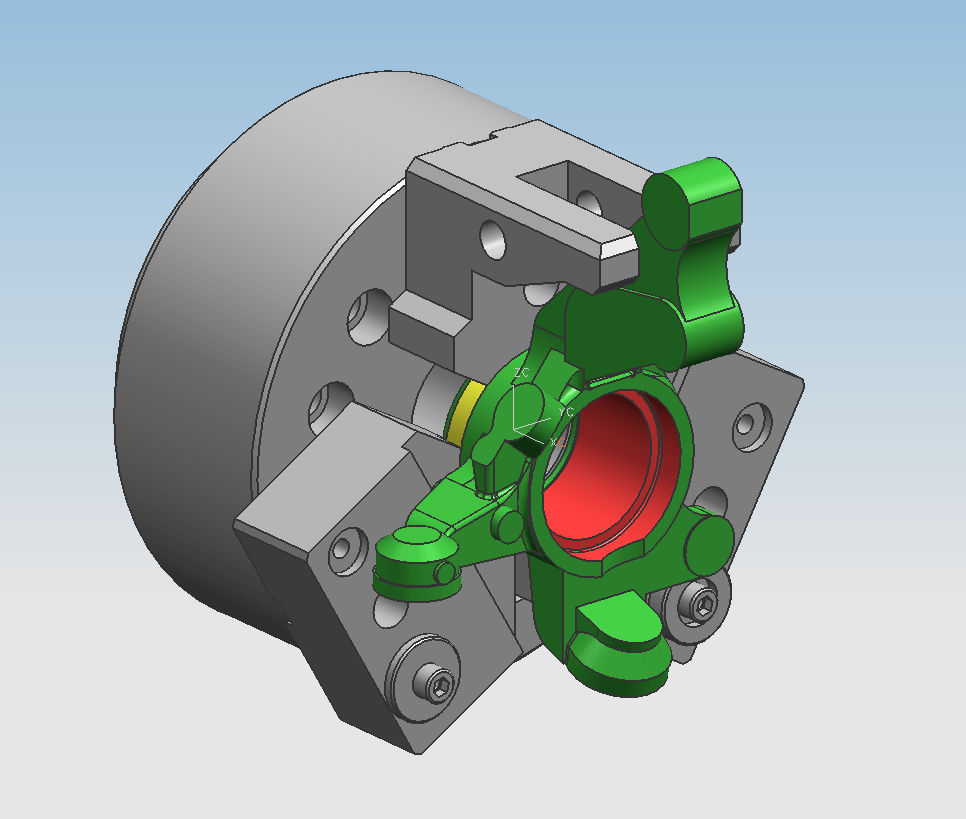

A fixture usually consists of a positioning element (to determine the correct position of the workpiece in the fixture), a clamping device, a tool guide element (to determine the relative position of the tool and the workpiece or to guide the direction of the tool), a dividing device (to enable the workpiece to complete the processing of several stations in one installation, and there are two types of rotary dividing devices and linear moving dividing devices), connecting elements and a fixture base (fixture base).

For example, welding fixtures, inspection fixtures, assembly fixtures, machine tool fixtures, etc., among which machine tool fixtures are the most common and are often referred to as fixtures. When processing a workpiece on a machine tool, in order to make the surface of the workpiece meet the technical requirements of size, geometry and relative position accuracy with other surfaces specified in the drawing, the workpiece must be installed (positioned) and clamped (clamped) before processing.

According to the usage characteristics, the types of fixtures can be divided into: ① Universal fixtures. Such as machine vises, chucks, suction cups, dividing heads and rotary tables, etc., have great versatility and can better adapt to the changes in processing procedures and processing objects. Their structures have been finalized, and their sizes and specifications have been serialized. Most of them have become a standard accessory for machine tools. ② Special fixtures. They are specially designed and manufactured for the clamping needs of a certain product part in a certain process. They serve a specific object and are highly targeted. They are generally designed by the product manufacturer. Commonly used ones include lathe fixtures, milling machine fixtures, drilling jigs (machine tool fixtures used to guide the tool to drill or reame holes on the workpiece), boring dies (machine tool fixtures used to guide the boring bar to bore holes on the workpiece) and accompanying fixtures (mobile fixtures used on the automatic line of combined machine tools). ③ Adjustable fixtures. Special fixtures that can replace or adjust components. ④ Combination fixtures. The fixtures, which are composed of standardized components of different shapes, specifications and uses, are suitable for new product trials and single-piece, small-batch production and temporary tasks with frequent product changes. In addition to vises, chucks, indexing heads and rotary tables, there is a more common tool holder. Generally speaking, when the word tool holder appears at the same time, most of the fixtures refer to tool holders. Hangzhou Xiongchu Technology Co., Ltd. is dedicated to serving you.

Home