The ten most practical fixtures in machining

In the world of machining, precision fixtures are like right-hand men. Their practicality and efficiency cannot be ignored. Here are the top ten fixtures we carefully selected. They not only play a key role in daily work, but also embody the model of coexistence of technological innovation and practicality.

1. Chuck: As the cornerstone of machining, the chuck is an evergreen in the workshop with its enduring practicality and wide application. Without the chuck, the lathe seems to have lost its soul.

2. T-type workbench: It may seem inconspicuous, but the T-type workbench is essential for the stability and flexibility of the machine tool. Without it, the operator may be in trouble.

3. The combination of T-block, screw, pressure plate and nut: This seemingly simple combination is actually an essential tool for the assembly of milling machines and machining centers. Their tacit cooperation ensures efficient clamping.

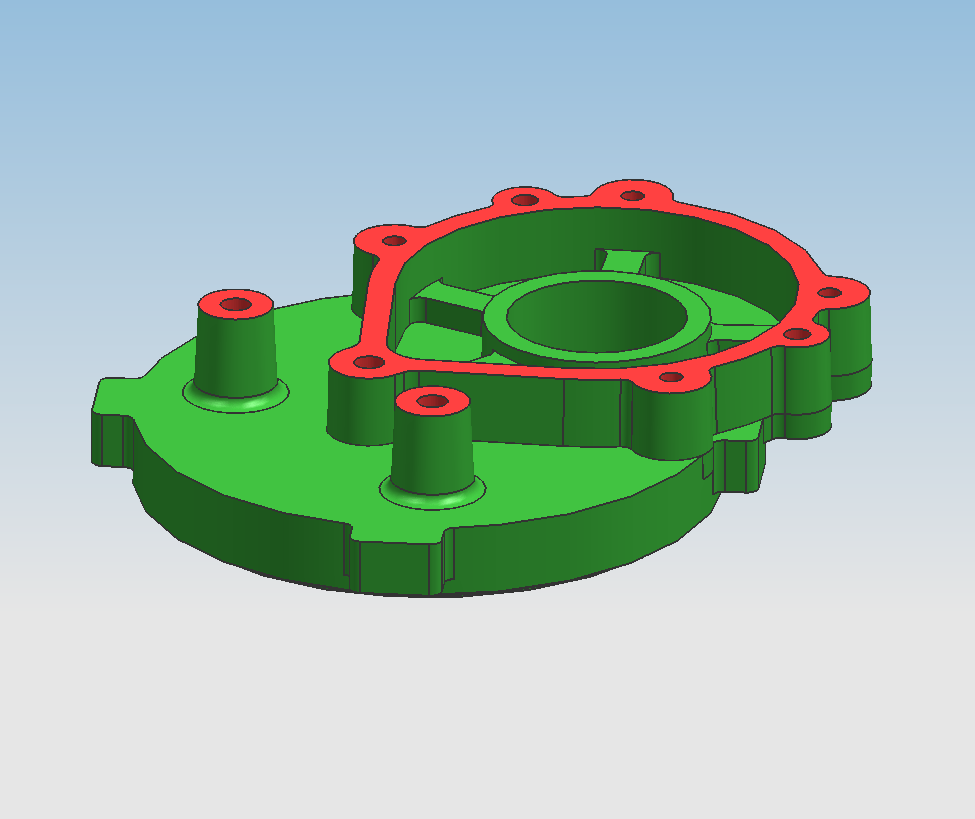

4. EROWA fixture: With its excellent repeatability, EROWA fixture is a capable partner for electrode, four-axis and five-axis machining, with an amazing accuracy of +/-0.002mm.

5. Vises and Maxes: For parts that are difficult to fix with pressure plates, vises and maxes provide the last line of defense to ensure the stability of complex workpieces.

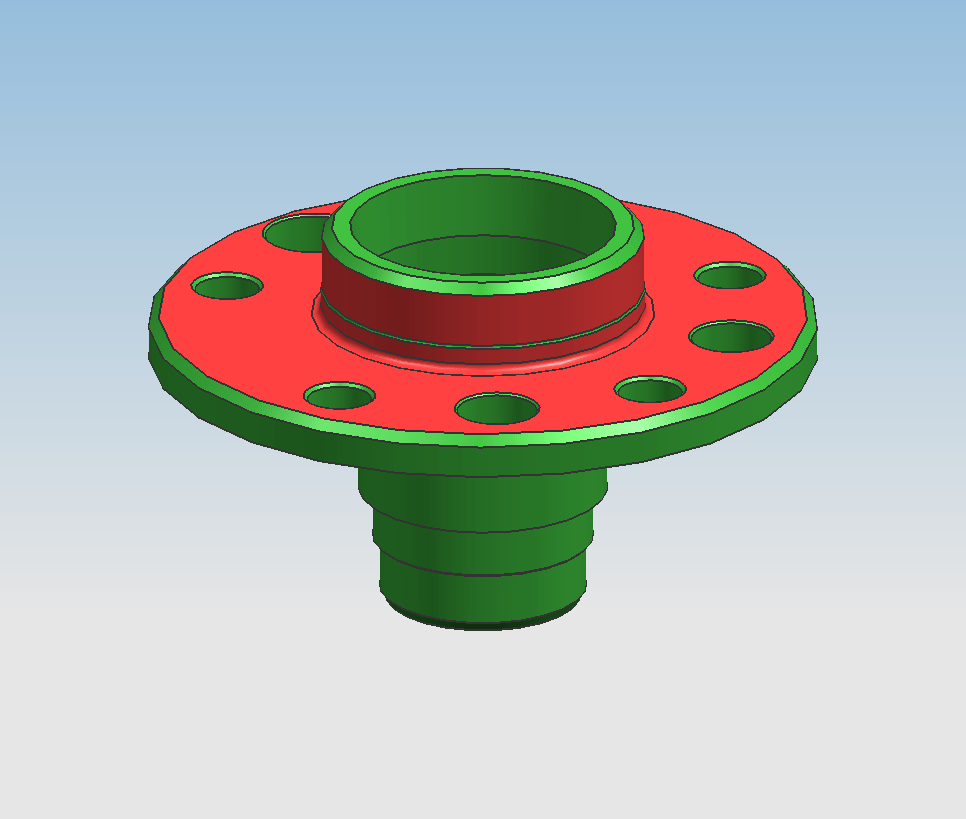

6. Spindle and toolholder: The crystallization of intelligence and technology, spindle and toolholder are the key to high-precision processing, showing the excellence of human wisdom.

7. Magnetic platform: For parts without fixed holes, the magnetic platform provides a simple and convenient clamping solution, making the processing process smoother.

8. Spring collet/collet: A flexible choice to solve the clamping problem of tools of various specifications, saving tool replacement time and improving production efficiency.

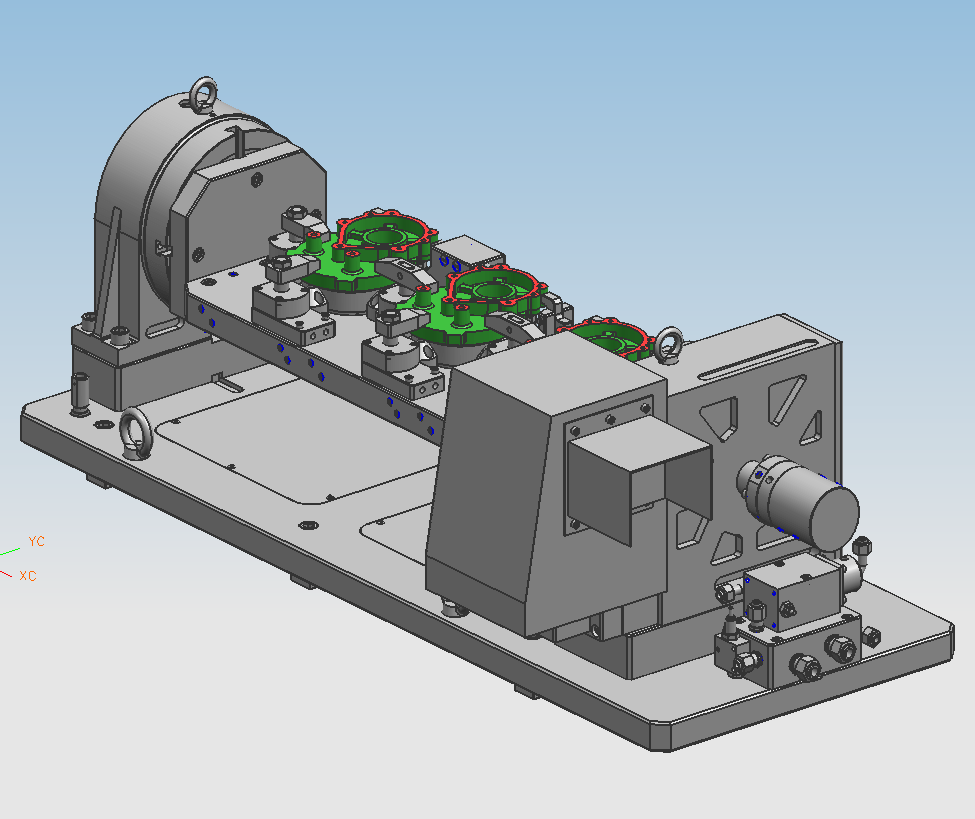

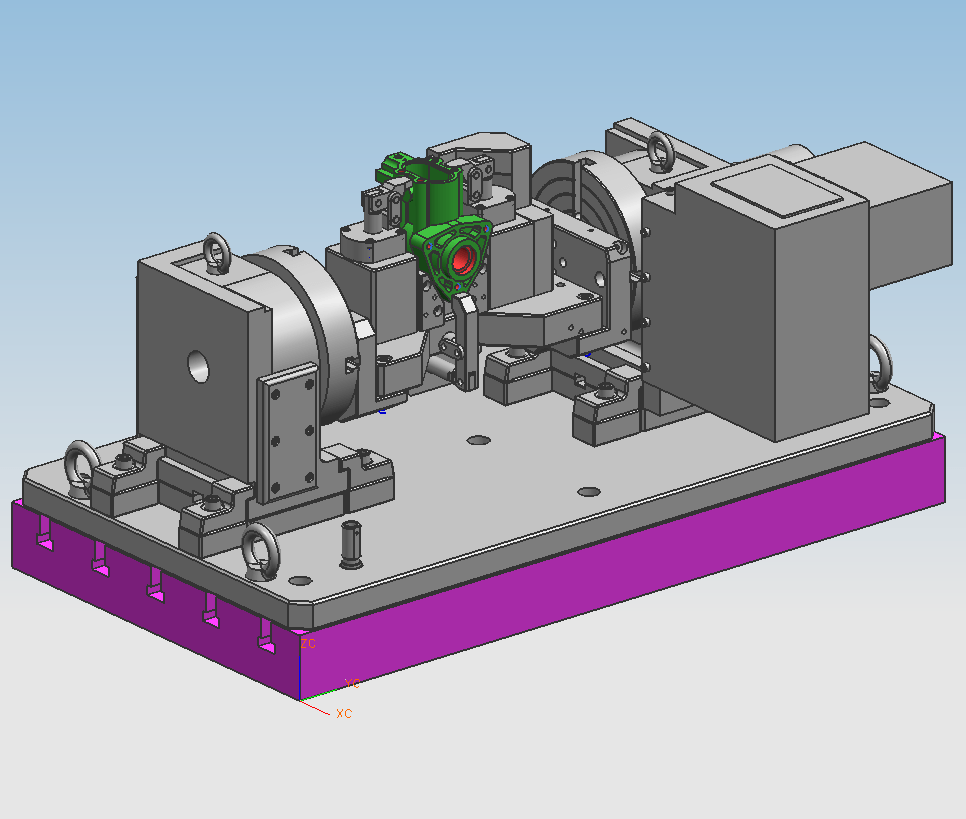

9. Pneumatic cylinder clamp: As a favorite of workers, pneumatic clamps have improved production efficiency and reduced labor burden with their advantages of automatic clamping.

10. Dividing head: Although it was once popular, the popularity of dividing spindles has caused the status of dividing heads to decline, but it is still indispensable in certain specific scenarios.

在机械加工的世界里,精密夹具犹如得力助手,它们的实用性和效率不容忽视。以下是我们精心挑选出的十大夹具,它们不仅在日常工作中扮演着关键角色,还体现了技术创新与实用性并存的典范。

1. 卡盘</:作为机械加工中的基石,卡盘以其经久不衰的实用性和广泛的应用,堪称车间里的常青树。没有卡盘,车床仿佛失去了灵魂。

2. T型工作台</:看似不起眼,但T型工作台对于机床的稳定性和灵活性至关重要,没有它,操作者可能会陷入困境。

3. T型块、螺杆、压板和螺帽的组合</:这个看似简单的组合,实则是铣床和加工中心装配的必备工具,它们的默契配合保证了高效装夹。

4. EROWA夹具</:以其卓越的重复定位精度,EROWA夹具是电极、四轴和五轴加工的得力伙伴,精度达到惊人的+/-0.002mm。

5. 虎钳与麦司</:对于难以用压板固定的部分,虎钳和麦司提供了最后一道防线,确保了复杂工件的稳固。

6. 主轴与刀柄</:智能与科技的结晶,主轴与刀柄是实现高精度加工的关键,展示了人类智慧的卓越。

7. 磁力平台</:对于无固定孔位的零件,磁力平台提供了简单便捷的装夹解决方案,让加工过程更为流畅。

8. 弹簧夹套/夹筒</:解决多种规格刀具装夹问题的灵活选择,节省刀具更换时间,提高生产效率。

9. 气压缸夹具</:作为劳动者的心头好,气压夹具以其自动装夹的优势,提升了生产效率,减轻了人工负担。

10. 分度头</:尽管曾风光一时,但分度主轴的普及让分度头的地位有所下滑,但它在某些特定场景下依然不可或缺。

The following factors need to be considered when choosing a high-precision fixture manufacturer:

1. Design capability: The manufacturer’s design capability is an important factor affecting the quality of high-precision fixtures. Choose a manufacturer with a professional design team, rich experience and advanced design technology.

2. Processing accuracy: The processing accuracy of the fixture directly affects the quality of the final product. Choose a manufacturer with high-precision processing equipment and professional processing technology.

3. Manufacturing capability: The manufacturing of high-precision fixtures requires a high level of manufacturing capability. Choose a manufacturer with advanced manufacturing technology and rich manufacturing experience.

4. Service capability: The use of high-precision fixtures requires timely and thoughtful service. Choose a manufacturer with a professional technical service team and a complete after-sales service system.

5. User reputation: Understand the user’s evaluation and reputation of the high-precision fixtures produced by the manufacturer through online searches, industry associations and other channels.

Considering the above factors comprehensively, it is a better choice to choose a high-precision fixture manufacturer with reliable quality, thoughtful service and high cost performance.

- Design capability

- Processing accuracy

- Manufacturing capability

- Service capability

- User reputation