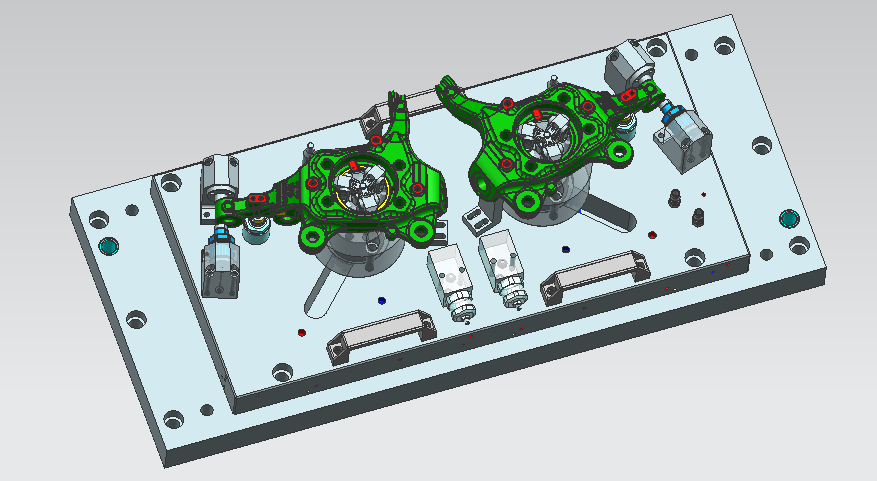

Universal Fixture 通用夹具

$35.00

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nulla congue vitae sem nec fermentum. Maecenas tincidunt semper cursus. In sit amet posuere augue. Curabitur tempus nec justo et consequat. Aliquam non ex lectus. Etiam vel ultricies felis. In sed mauris felis. Duis egestas nec quam at vulputate. Nulla nec odio rhoncus, gravida mi congue, bibendum urna. Fusce vel iaculis tortor. Praesent lacus justo, blandit non molestie sit amet, iaculis vitae nunc. Ut sapien diam, lobortis non metus non, fringilla molestie ante. Mauris nisl quam, ultricies a fringilla ac, rutrum nec dolor. Cras luctus viverra odio.

Description

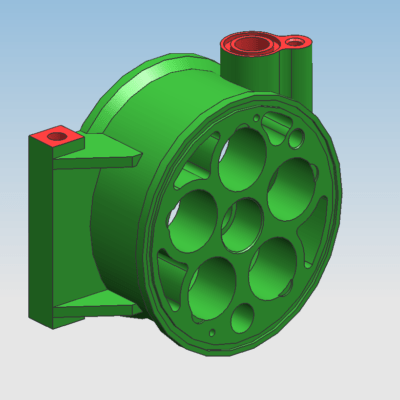

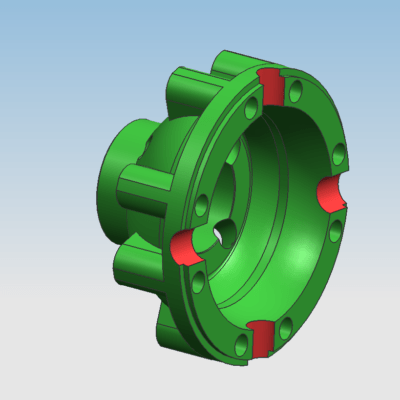

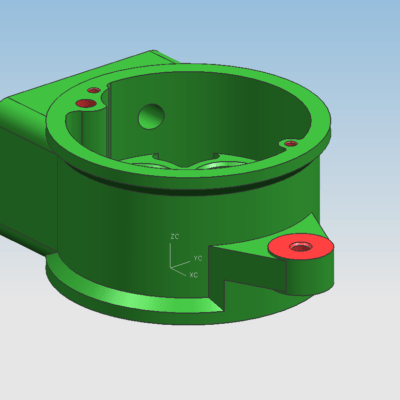

A fixture is a process device used to quickly fasten the workpiece during processing so that the machine tool, tool, and workpiece maintain the correct relative position. That is to say, workholding fixtures are indispensable components of mechanical processing. Driven by the development of machine tool technology towards high speed, high efficiency, precision, composite, intelligent, and environmentally friendly, fixture technology is developing towards high precision, high efficiency, modular, combined, universal, and economical directions.

Fixtures are also called fixtures. In a broad sense, any device used to quickly, conveniently, and safely install workpieces in any process in the process can be called a fixture. For example, welding fixtures, inspection fixtures, assembly fixtures, machine tool fixtures, etc. Among them, machine tool fixtures are the most common, often referred to as fixtures.

When processing workpieces on machine tools, in order to make the surface of the workpiece meet the technical requirements of size, geometry, and relative position accuracy with other surfaces specified in the drawings, the workpiece must be installed (positioned) and clamped (clamped) before processing.

The application of machine tool fixtures is conducive to ensuring the processing accuracy of workpieces and stabilizing product quality; it is conducive to improving labor productivity and reducing costs; it is conducive to improving workers’ working conditions and ensuring safe production; it is conducive to expanding the process range of machine tools and realizing “one machine for multiple uses”.

The fixture is usually composed of positioning elements (determining the correct position of the workpiece in the fixture), clamping devices, tool setting guide elements (determining the relative position of the tool and the workpiece or guiding the direction of the tool), indexing devices (enabling the workpiece to complete the processing of several stations in one installation, there are two types of rotary indexing devices and linear moving indexing devices), connecting elements and fixture bodies (fixture bases), etc.

The use of fixtures is also very high in electronic manufacturers. In order to improve production efficiency and product quality in production, tooling fixtures are often used in the middle and later stages of production for functional testing or auxiliary assembly (can assemble a fixed shape and height, etc.). The actual use in electronic manufacturing plants is very wide. Because it is non-standard customization, there is nothing that cannot be done.

夹具是加工时用来迅速紧固工件,使机床、刀具、工件保持正确相对位置的工艺装置。也就是说Workholding工装夹具是机械加工不可缺少的部件,在机床技术向高速、高效、精密、复合、智能、环保方向发展的带动下,夹具技术正朝着高精、高效、模块、组合、通用、经济方向发展。

夹具又称卡具。从广义上说,在工艺过程中的任何工序,用来迅速、方便、安全地安装工件的装置,都可称为夹具。例如焊接夹具、检验夹具、装配夹具、机床夹具等。其中机床夹具最为常见,常简称为夹具。

在机床上加工工件时,为使工件的表面能达到图纸规定的尺寸、几何形状以及与其他表面的相互位置精度等技术要求,加工前必须将工件装好(定位)、夹牢(夹紧)。

应用机床夹具,有利于保证工件的加工精度、稳定产品质量;有利于提高劳动生产率和降低成本;有利于改善工人劳动条件,保证安全生产;有利于扩大机床工艺范围,实现“一机多用”。

夹具通常由定位元件(确定工件在夹具中的正确位置)、夹紧装置、对刀引导元件(确定刀具与工件的相对位置或导引刀具方向)、分度装置(使工件在一次安装中能完成数个工位的加工,有回转分度装置和直线移动分度装置两类)、连接元件以及夹具体(夹具底座)等组成。

夹具在电子厂商使用也是非常高的,在生产中为了提高生产效率和产品质量,在生产的中段和后段就常用工装夹具来进行功能测试或者辅助装配(能装配出固定的外形及高度等)。实际在电子生产制造厂中的用途是非常广,因为是非标定制的,所以只有想不到而没有做不到的。

Reviews

There are no reviews yet.